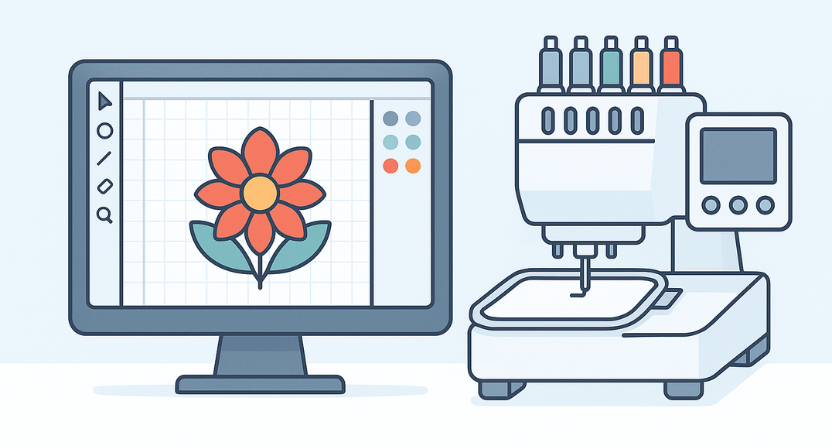

Embroidery is the traditional method of decorating fabrics, but technology has brought about significant improvements in how to create intricate designs. One of the biggest changes in embroidery digitizing is the use of CAD (Computer-Aided Design).

This digital approach allows designers to create accurate, complex, and consistent designs that were once impossible with traditional hand stitching.

Let’s explore what exactly this technique brings to the table in the embroidery process in this blog.

How CAD Transforms Traditional Embroidery

Before this technology, embroidery required skilled hands to stitch every detail. While this process produced beautiful, handcrafted items, it was also time-consuming and prone to errors. CAD technology has simplified this by converting designs into machine-readable files.

With this software, designers can create or import designs and convert them into a digital file format that the embroidery machine can understand. This includes specifying details like

- Type of stitch,

- The direction of the stitch,

- Thread colors

- Size of the design.

Once the design is converted into this digital format, the embroidery machine can execute it with precision.

The Primary Benefits of Using CAD for Embroidery Digitizing

There are several advantages to using CAD in embroidery digitizing, especially for businesses looking to improve the quality and efficiency of their embroidery projects:

Increased Precision

It allows designers to control every aspect of the design, from stitch direction to the type of stitch used. This precision is difficult to achieve in Handcrafted embroidery.

Efficient Output

Once a design is digitized, it can be loaded into the embroidery machine and stitched in a fraction of the time. Machines can execute these digital designs quickly, making them ideal for businesses.

Uniformity in Designs

One of the biggest benefits of using this technique is the consistency it offers. Once the design is digitized, it can be repeated on multiple fabrics. This is essential for businesses that need to maintain brand consistency.

Complexity and Customization

This technique makes it easier to create complex designs that may be impossible or impractical to create by hand, whether it’s fine detailing, gradients, or intricate logos.

Flexibility for Adjustments

If you need to modify a design, this technology allows for easy adjustments. Whether it’s resizing the design for different products or changing thread colors, you can do so with just a few clicks.

The Types of Stitches Used in Embroidery Digitizing

While this technique makes it possible to automate the embroidery process, it also offers various stitch types to optimize the look of the final product. Some of the most common stitches used in embroidery digitizing include:

- Satin Stitches

- Fill Stitches

- Running Stitches

Check out Types of Stitches Used in Embroidery Digitizing for complete details.

By using CAD software, designers can experiment with these stitches and adjust their settings to suit different fabric types and design requirements.

Choosing the Right Fabric for Embroidery Digitizing

When it comes to embroidery digitizing, selecting the right fabric is crucial to achieving a high-quality, durable result. Different fabrics have unique properties that affect how well they hold embroidery designs, and choosing the right one can make all the difference.

Among the many fabric options, cotton is often considered an excellent choice, but it’s important to understand its benefits and how to make the most out of it for your embroidery projects.

The Future of CAD in Embroidery Digitizing

As embroidery technology continues to change, the role of CAD in the digitizing process is only going to expand. With advancements in software and machine capabilities, designers will have even more tools at their disposal to create high-quality, customized designs.

Whether you are looking to create custom logos for your business or want to experiment with embroidery at home, Impact Digitizing will continue to shape the future of this art form.

FAQs

1. How Does CAD Improve Embroidery Precision?

CAD software allows designers to control every aspect of the stitch pattern, ensuring greater precision and consistency, even for complex designs.

2. Can CAD Be Used For Large Production Runs?

Yes, CAD digitizing allows for faster production times, making it ideal for businesses needing to produce large quantities of embroidered items quickly.

3. What Types of Stitches are Commonly Used in Embroidery Digitizing?

Common stitches include satin stitches, fill stitches, and running stitches, each serving different purposes depending on the design.

4. Why is Cotton a Good Choice For Embroidery?

Cotton is soft, versatile, and holds embroidery threads well, but it’s important to pre-wash cotton to prevent shrinkage during the embroidery process.

5. Can CAD Software Be Easily Adjusted For Custom Orders?

Yes, CAD allows for quick modifications to designs, such as resizing or changing thread colors, making it perfect for custom embroidery projects.